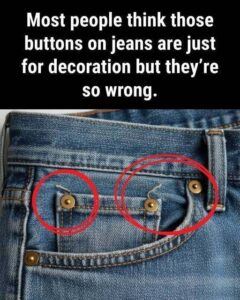

Most people pull on a pair of jeans without a second glance at the tiny metal dots near the pockets, often dismissing them as purely decorative accents intended to give denim a rugged, “authentic” look. However, these small fasteners, known as rivets, were born out of pure industrial necessity in the 1870s. Before jeans became a global fashion staple, they were essential gear for miners, railroad workers, and cowboys who found that standard denim seams could not withstand the mechanical stress of heavy labor. A tailor named Jacob Davis noticed that pockets frequently ripped under pressure and innovated a solution by using copper rivets—typically found in industrial settings—to reinforce these weak spots. Lacking the funds to protect his idea, Davis partnered with his fabric supplier, Levi Strauss, and together they patented the riveted jean in 1873, prioritizing durability over aesthetics.

The mechanical function of a rivet is as simple as it is effective: it spreads tension across a wider surface area, preventing the fabric from tearing at a single high-stress point. Usually crafted from copper or brass for their resistance to rust and ability to handle immense pressure, these rivets are strategically placed at the corners of front pockets where movement and weight create the most strain. In the early days of denim, rivets were even more prominent, appearing near the fly and on the back pockets. However, history reflects a constant evolution of this design; for instance, back-pocket rivets were eventually removed or relocated after horseback riders complained that the metal scratched their leather saddles. This shift demonstrates how the “visible engineering” of jeans has always been a balance between functional strength and practical comfort.

As denim transitioned from specialized workwear into a cultural icon of the 20th century, the rivet evolved into a symbol of denim craftsmanship. While modern manufacturing has introduced reinforced stitching that can often replace the need for metal hardware, many premium brands continue to include rivets as a mark of authenticity and tradition. This creates a split in the modern market: some consumers prefer “rivet-free” jeans for a sleeker look and a more comfortable fit during travel, while denim enthusiasts insist on copper rivets as a connection to an era when clothing was measured by longevity rather than fleeting trends. For these purists, a pair of jeans without rivets feels incomplete, lacking the historical weight of the original patent.

Today, after more than 150 years, the rivet remains the unseen foundation of denim design, surviving through every shift in style from skinny to baggy silhouettes. Even as fabrics become softer and more infused with stretch, the physical stress points of a garment remain, and rivets ensure the material stays together long enough to develop a perfectly worn-in feel. They serve as a permanent reminder of the problem-solvers of the 19th century and the industrial innovation required to build clothing that could survive a frontier. When you wear a pair of jeans, you are not just wearing a fashion choice; you are wearing a piece of visible engineering—a tiny, powerful detail that proves some of the best solutions are the ones that never need to change.